Silicon: The Secret Ingredient Powering Your Electronic Devices

Most people rely on many technological devices in their day-to-day life. For the average person, computers, cell phones, and many other devices are a daily staple for work or pleasure. Although technology has embedded itself into everyday life, few people understand the inner workings of their devices — how the phones they need and the computers they use to operate. Silicon is the fundamental component of smartphones and computers

Silicon: What It Is and How it Works

Silicon is the second most prominent chemical element on the earth and the secret force driving our devices. The element is a powerful semiconductor that is used in almost every electrical device you can think of. Part of what makes silicon an excellent element for semiconductors is its lack of impurities and micro-particles—it is an extremely clean and easy to use element. Modern semiconductors need impeccably pure substrates to do their job. Silicon wafers are the name designated to the engineered silicon component that goes into our devices.

Why Silicon Is a Great Semiconductor

Silicon is a highly used semiconductor due to its malleability and mobility at both high and low temperatures. Additionally, the element performs very well at room temperature. Other chemical conductors are utilized in specific products and applications, but silicon is the universal semiconductor in tech products. Its ability to quickly pass electrical currents through conductors makes it the top choice for manufacturers.

How Silicon Wafers Are Used in Technological Devices

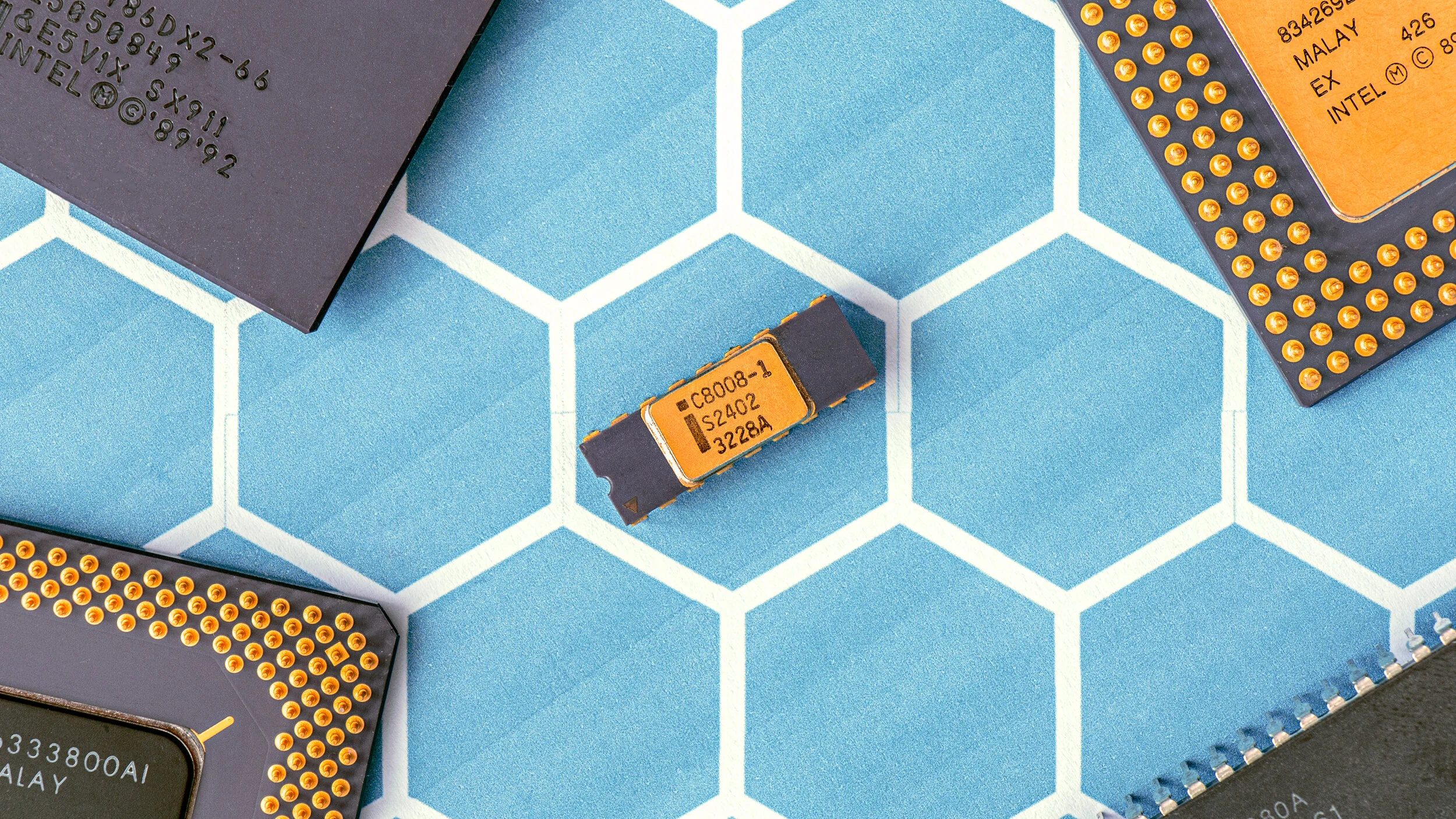

Silicon wafers are used as semiconductors in the production of chips and microchips in most of the commonly used electronic devices. These highly conductible components are used in creating integrated circuits, which control the way electrical currents move through your devices. The integrated circuit is the command center for most modern technologies sending currents in different directions when they are needed.

Silicon Wafer Dicing: How it Works

Engineers refer to each individual silicon wafer as a die. Manufacturers and engineers use the process of silicon wafer dicing to alter the chemical composition of silicon to have different properties. After an individual silicon wafer has been created, they will be diced to create integrated circuits. The dicing process could involve sawing, laser cutting, and scribing. After dicing, the individual silicon chips are put into carriers that are then used in the creation and manufacturing of electronic devices.

It is often easy to overlook the processes that power the contemporary world. Huge technological innovations have made our devices smaller and sleeker. Silicon is the fundamental element powering the world's modern devices.